In depth

The Follo Line Project

Powering Norway’s largest infrastructure project

The longest railway tunnel in the Nordic countries relies on Rectiverter systems to power critical applications

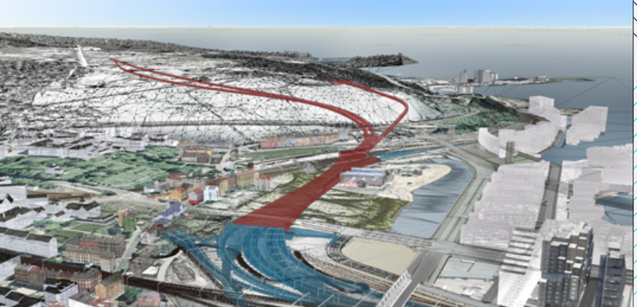

The Follo Line Project features a new double track railway going south-east out of Oslo Central Station to the regional town of Ski. It includes the longest railway tunnel line in the Nordic countries. At a projected cost of NOK 25 billion (approx. USD 3 billion), the Follo Line is currently the largest infrastructure project in Norway.

It is also a truly international project. The main contractors are Spanish and Italian, supported by numerous subcontractors from Norway and all over Europe. Over 40 nationalities are represented in the work force that counts several thousand people over the 6 year building period, between 2015 to 2021.

Bane NOR’s choice of Rectiverter power is a stamp of quality, and a recognition of the unique advantages that our innovative concept offers

Jon Henry Odelskiold, Sales Manager Nordic

However, Bane NOR (the state-owned company responsible for the national railway infrastructure in Norway) did not have to search far and wide to find the supplier of choice for power systems. Drammen, Eltek’s home town, is just a 30 minutes train ride to the west of Oslo.

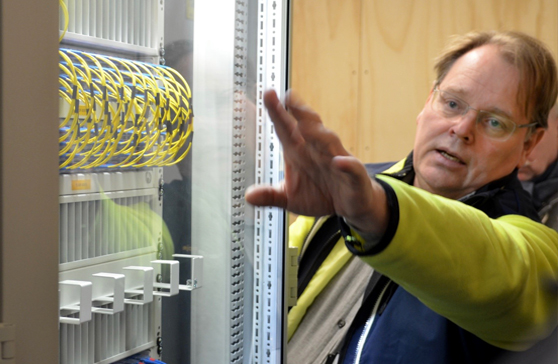

Sales Manager Nordic at Eltek, Jon Henry Odelskiold (left) and Technical Manager for the Follo project, Hans Christian Kruse, both agree that the Rectiverter is the best UPS choice, with its modular architecture, compactness and multi-application capabilities

Rectiverter breakthrough

Spirits were high and the occasion called for spontaneous celebration in the offices of the Nordic Sales department when the message came through: Bane NOR had decided to go for Eltek’s Rectiverter-based power concept in the Follo Line project. Bane NOR´s main priorities are safety, reliability and performance. Unexpected interruption of the train services through the tunnel, with or without safety consequences, is just not an option. When it comes to power, this means putting in place uninterrupted power supply for the critical applications that will secure continuous operation. – Bane NOR’s choice of Rectiverter power is a stamp of quality, and a recognition of the unique advantages that our innovative concept offers. We see this contract as a great breakthrough for the Rectiverter in the market, says Jon Henry Odelskiold, Sales Manager Nordic and Key Account Manager at Eltek for Bane NOR.

The article continues under the video

The world’s first bidirectional, power conversion module

Gigantic dimensions, impressive precision

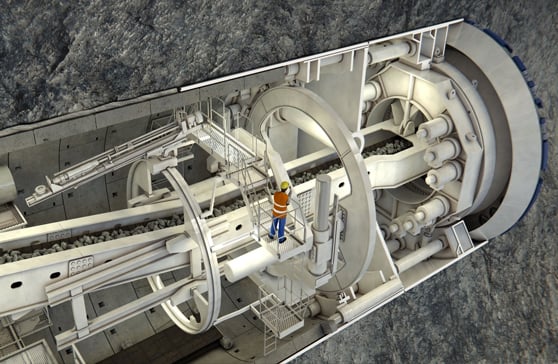

The Follo Line is a new 22 km underground double track high-speed railway that will cut travel time between Oslo and Ski in two, to 11 minutes. The main tunnel is 22 km long, between its connecting point with the Oslo Central Station infrastructure deep down below the Ekeberg hill, and the station area at Ski, at 125 m above sea level. The tunnel is in fact two tunnels, serving rail traffic in opposite directions. As this article is being written, four gigantic TBMs – tunnel boring machines – are eating their way through the rock, at a speed of 15 meters a day. From their starting point at Åsland, mid-way between Oslo and Ski – two are heading towards Ski and two towards Oslo. As they go, they seal the tunnel roof and walls behind them, using concrete segments, manufactured in a purpose-built concrete factory at Åsland. Breakthrough is planned for end of 2018 / start of 2019, with a 15 cm deviation tolerance.

Every 500 meters, there is a cross passage between the two main tunnel tubes – 50 of them in total. They provide emergency access to the other tube. This is also where technical installations are installed, including the Rectiverter UPS systems

Hans Christian Kruse, Technical Manager Follo Line project

One of four tunnel boring machines at work. No daylight and a bleak environment for the giant stone grinders gnaw their way towards Oslo and Ski

Limited space and time

Impressive as this may sound, there will definitely not be a “hall of the mountain king” feeling down there in the tunnel. Rather the opposite, according to Hans Christian Kruse, technical manager for the Follo Line project. - The trains will occupy the tunnel space, with a narrow escape platform running along one side of the tunnel. Every 500 meters, there is a cross passage between the two main tunnel tubes – 50 of them in total. They provide emergency access to the other tube. This is also where technical installations are installed, including the Rectiverter UPS systems. – So space is really limited, says Kruse, and adds: And so is time for installation and testing.

The tunnel boring machine is like an underground factory, drilling and sealing the tunnel at a speed of 15 metres per day

4 hour service window

The new Follo Line will be a busy one, with trains passing through the tunnel day and night, transporting people in and out of Oslo to and from the south. Only 4 out of 24 hours will be quiet and available for inspection and service of the tunnel and its installations. The limitations of space and time, in combination with very demanding requirements when it comes to safety, reliability and overall performance, have defined the yardstick against which Bane NOR have evaluated the in-coming offers, explains Hans Christian Kruse.

- The less equipment we have down there, the better it is from a servicing point of view. And the less inspection and service installed equipment requires, the better it is. Just think about it – there is no way we could inspect, let alone service or repair, 50 cross passages in 4 hours, says Kruse.

This is also why Bane NOR is currently looking into the advantages of the Multisite Monitor fleet management system. This will allow them to have a complete and real-time overview of the status of all their Eltek power systems, the ability to detect potential faults before they occur, and to manage and optimize their power network – all from a remote, networked terminal.

Critical applications make power critical

The Rectiverter systems will supply uninterrupted power for applications that are absolutely essential for safe operation of the tunnels and the train services. The signalling system keeps track of the traffic, and keep the trains on time, much like the air traffic control, only for trains.

Learn more about relevant applications for the Rectiverter

Another critical application is the GSM-R system, the rail-internal mobile communication network that allows communication between the rail traffic control center and the train driver. A third area is emergency systems, e.g. emergency illumination and fire extinguishing equipment. – These applications are critical for safe and stable operation, and so the power systems that guarantee their uptime, become critical too. This is why we at BaneNOR will not leave it up to contractors to decide which UPS to install. That is a critical decision that we need to make ourselves, says Hans Christian Kruse

Discipline Engineer Telecommunications Kenneth Nyborg is responsible for the telecom installations in the Follo Line project. Rectiverter systems from Eltek will provide both AC and DC power required to run the GSM-R network

The greatness of compactness

There is a perfect match between the requirements and the unique qualities offered by the Rectiverter systems. The modular architecture makes it very easy to service and expand the systems. Modules can be hot-swapped, and new modules can be added. The well-known Flatpack quality is taken one step further, as there is no longer a mechanical switch and a potential single-point-of failure. – But the real beauty of the Rectiverter systems is that one setup can power all the required applications, with one shared battery bank. Previously, there had to be one UPS system per application, one for Signalling, one for GSM-R and one for low-voltage emergency applications, and each one with its own separate battery bank. “Not so anymore, with the versatile Rectiverter that accepts both AC and DC input and output across a wide voltage range, “compact” has taken on a new meaning. - Space is as such a scarce commodity down there, and the old “one-UPS-per-application” model is just not feasible”, says Jon Henry Odelskiold.

In addition, the battery bank is now based on Li-Ion batteries, which saves further space and prolongs the battery lifetime.

A new era

For both Eltek and Bane NOR, and not to forget the train passengers, the Follo Line project is an important milestone and somewhat of a watershed. Bane NOR have demonstrated their willingness and ability to go for groundbreaking new solutions in order to build a sustainable and modern public transport offering, and in order to serve their customers in the best possible way. For Eltek, it is an important reference that clearly demonstrates the value of the Rectiverter and points the way ahead in rail power.

About the Follo Line Project:

- New double track line between Oslo Central Station and the public transport hub at Ski

- 20 km long twin rail tunnel

- Extensive work at Oslo Central Station

- Construction of new station at Ski

- Realignment of existing Østfold Line

- Project under simultaneous production from five sites

- Scheduled completion Dec 2021

The project includes extensive work and expansions at Oslo Central Station

About the Rectiverter:

- Provides both 230 VAC and 48 VDC as input and output

- No single point of failure

- No need for static switch

- Extra charging capacity

- One common controller

- High-end solution

Learn more about the Rectiverter

Photo credit: Nicolas Tourrenc/Acciona Ghella Joint Venture